Energy Audit vs. Power Quality Audit – A few weeks ago, we discussed electrical hazards. Yes, as you might have guessed, the article covered many points on how to work safely, but do you know what electrical hazards are? You can read about them HERE.

Now, as the title suggests, let’s discuss why a power quality audit is just as important as an energy audit.

What is a Power Quality Audit?

Energy audits are designed to assess energy consumption within specific facilities like factories, mining operations, and various other sectors. They focus on kilowatts, measuring how much energy is consumed at a specific point in time, and kilowatt-hours, which tracks energy use over time.

An energy audit will tell you how much energy you consume and when. However, it doesn’t explain why you’re using that much energy. An energy audit is a useful first step in reducing energy consumption because it helps you establish a baseline for “normal” electrical usage and how to implement energy-saving strategies.

Power Quality Audits by PT Media Kontrol Utama

Now, About Power Quality Audits

A power quality audit measures how modern devices such as computers, LED lights, high-efficiency variable frequency drives, and motor controls impact the performance of your factory’s power distribution system.

In some cases, these devices generate harmonics due to their power supply. These harmonics (currents that can overload wires, create heat, and in extreme cases, cause fires) distort the sine wave moving through the system. This “dirty power” then affects the quality and condition of electricity within the factory, leading to circuit heating, motor failures, and system malfunctions.

In simple terms, if a factory regularly spends time, money, and resources replacing motors, variable frequency drives (VFDs), and other control equipment, it likely has harmonic distortion issues.

Harmonics are not limited to industrial sectors; any building with electronic devices and electrical flow is at risk. For example, water treatment plants, hospitals, office buildings, and schools all face potential harmonic issues.

Symptoms of harmonics often frustrate electricians, such as “We don’t know why this circuit breaker keeps tripping” or “We don’t understand why this UPS keeps shutting down.”

Don’t worry! These problems can be addressed and resolved.

However, solutions often require the expertise of professionals with equipment capable of identifying electrical symptoms or issues.

Power Quality Audits by PT Media Kontrol Utama

So, What Causes Harmonics?

Harmonic problems and electrical distribution systems cannot be identified with the naked eye. The process involves specialized power quality detection equipment installed temporarily or permanently depending on needs. After installation, monitoring begins, and power quality technicians evaluate the recorded data to determine possible solutions.

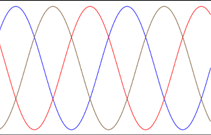

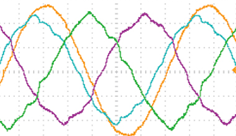

If harmonic issues are detected, filtering mechanisms will be needed. One solution is using Schneider Electric AccuSine Plus harmonic filters, which are very effective in neutralizing harmful harmonic effects. The AccuSine filter displays the sine waves of three-phase power flowing through the system and depicts the level of harmonic distortion. Once the filtering mechanism is activated, the sine wave returns to a normal s-shaped wave oscillating above and below zero. This filtering process will correct existing harmonics.

Desired clean sine wave

Unwanted harmonic distortion

Interested in resolving energy issues at your factory? Contact us now for a detailed explanation of electrical problems at your facility. Tschüs! 👷

Contact Us

For expert consultation and repair services for your power quality audit, reach out to PT Media Kontrol Utama. Our experienced professionals are ready to help you maintain the reliability and safety of your electrical distribution system.

Reference:

- Eaton, “Harmonic sources – What causes harmonics?”

https://www.eaton.com/us/en-us/products/controls-drives-automation-sensors/harmonics/harmonic-sources—what-causes-harmonics.html - Jason Heindel, Schneider Electric, “Why a power quality audit is as important as an energy audit?”

https://blog.se.com/power-management-metering-monitoring-power-quality/2021/07/07/why-a-power-quality-audit-is-as-important-as-an-energy-audit/ - Yokogawa, “Power Quality and Energy Efficiency for Power Measurements”

https://tmi.yokogawa.com/ca/library/resources/white-papers/power-quality-and-energy-efficiency-for-power-measurements/